Late-Model Corvair Three-Point Seatbelts

The first set installed was in a '65 Corsa. They were from JC Whitney and were manually adjustable - no inertia reels. Since I was the only one who drove the car, the driver's belt was adjusted once and there they stayed forever. A training session was required every time a new passenger rode with me. My installation was a little questionable but after a 35-mph impact with another vehicle, I am confident that what I did worked well enough to share with others.

My second installation was in a '66 coupe from which a Stinger clone was born. This time I purchased a set of belts with nice self-retracting inertia reels. I used the same installation method and I'm confident that they will do their job. I don't plan on testing them out anytime soon!

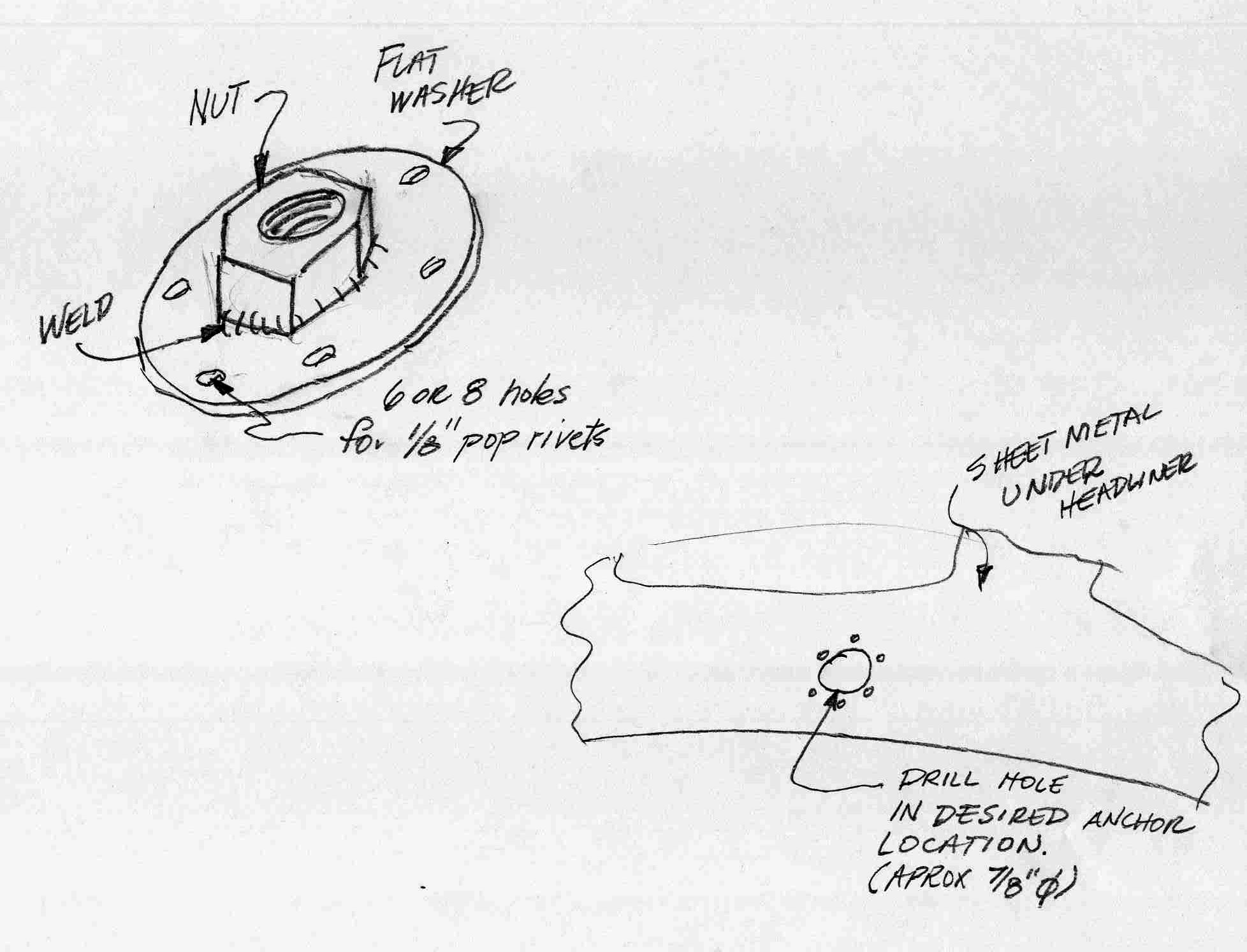

One regret: I wish I had taken some pictures as I was installing them. All I have are finished pictures. I've made a couple of crude sketches to show what I did.