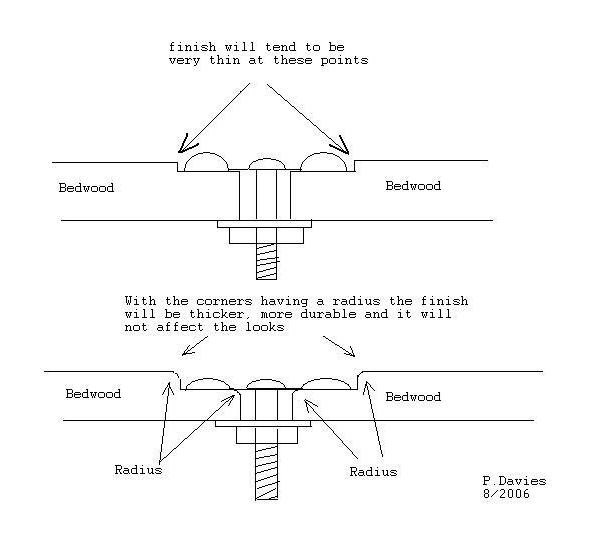

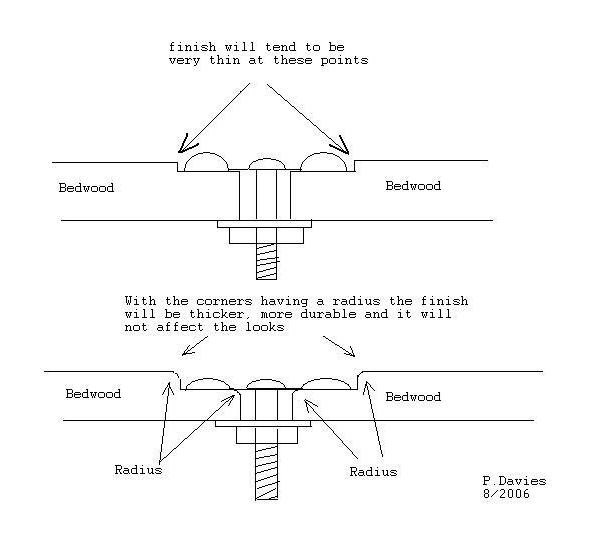

One of the most common reasons that the bed wood finish starts to fail prematurely is due to mechanical stress. These stresses are placed on the wood through expansion and contraction due to heat and cold or wet and dry weather. I have noticed that most of the finishes start to fail along the edges of the boards at the sides and the ends where the wood has a 90 degree edge. This is in part due to the fact that paint and any finish for that matter is always thinner on the corners and edges. This is the reason that when detailing or sanding a paint job one is always informed to STAY OFF THE EDGES. Instead of cutting the edges and ends at such a sharp angle have them routered using a half round bit. This would make a rounded edge instead of the 90 degree edge and help eliminate stress on the finish at these points. Also a lot of folks only finish the top of the wood that will be displayed. The underside, edges and ends of the wood will pick up a lot of moisture from the ground and the air. These areas also need to be sealed, varnished or painted. This will greatly prolong the finish on the top side.

Pete Davies, Antioch, California